1. The tool cabinet adopts three piece lapping design, high-quality cold-rolled steel plate, cutting, punching, folding, welding and other processes with advanced numerical control equipment, and adopts advanced automatic electrostatic spraying process for surface treatment. Beautiful, strong and durable.

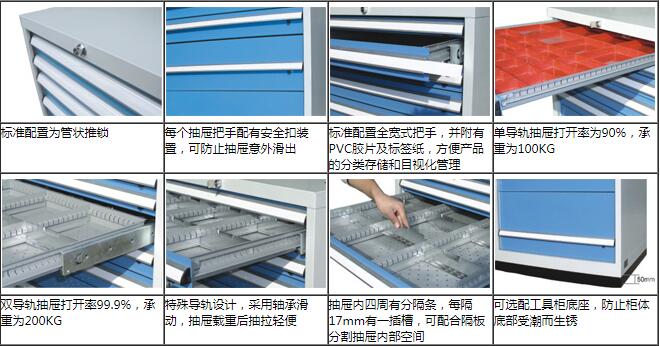

2. The drawer is overloaded with special guide rails. The single guide rail bears 100kg, the opening rate is 92%, the double guide drawer bears 200kg, the opening rate is 99.9%. The bearing is used between drawer and guide rail, which is flexible in pushing and pulling.

3. The horizontal and vertical panels in the drawer can be adjusted freely, and different sizes of items can be stored separately. They can also be separated by a modular part box.

4. The drawer with limit device will not fall when it is pulled out; it can also be equipped with safety buckle, so that the drawer will not slide out by itself, and it can be used reliably.

5. The whole tool drawer is locked on all drawers with locks, so it is easy to use.

6. Users can assemble their own satisfactory tool cabinets according to the recommended width (W), depth (d) and height (H) dimensions. Single track or double track drawers can also be configured in the same tool cabinet to meet the needs of users.

7. Options on the top of the tool cabinet: Green Stripe rubber, envelope, drawing board, active back board, square hole hanging board or shutter hanging board, increase the utilization rate of the tool cabinet.

8. The bottom of the tool cabinet can be selected as: flat pad, rectangular pad, angle pad and adjustment pad, which are suitable for different placement requirements of users.

9. After the caster is installed, the tool cabinet will become a mobile tool cabinet (tool car).