Attic shelf advantage:

1. Complete assembly structure, easy assembly, installation and disassembly;

2. Column, main girder and sub-girder material cross-section optimization, strong bearing capacity;

3. The surface is treated by electrostatic powder spraying, and the appearance is beautiful.

4. It can be flexibly designed into two or more layers according to the actual site needs. Suitable for storage of multi-varieties, small batches of goods, make full use of space;

5. The lower layer is the form of shelf, and the upper layer can be platform or shelf structure. The bottom floor can be used for storage materials and floor support to maximize flexibility.

Details of attic shelves:

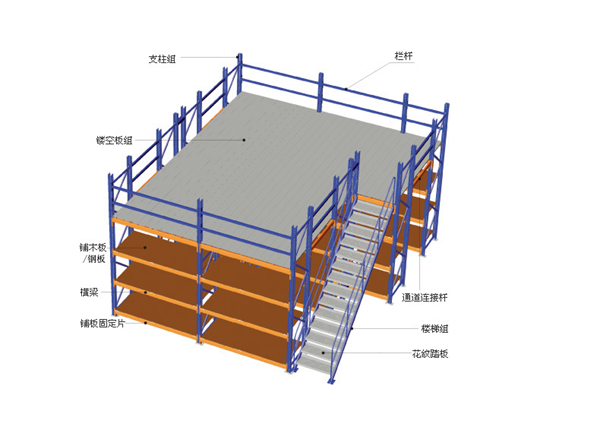

Loft shelf structure:

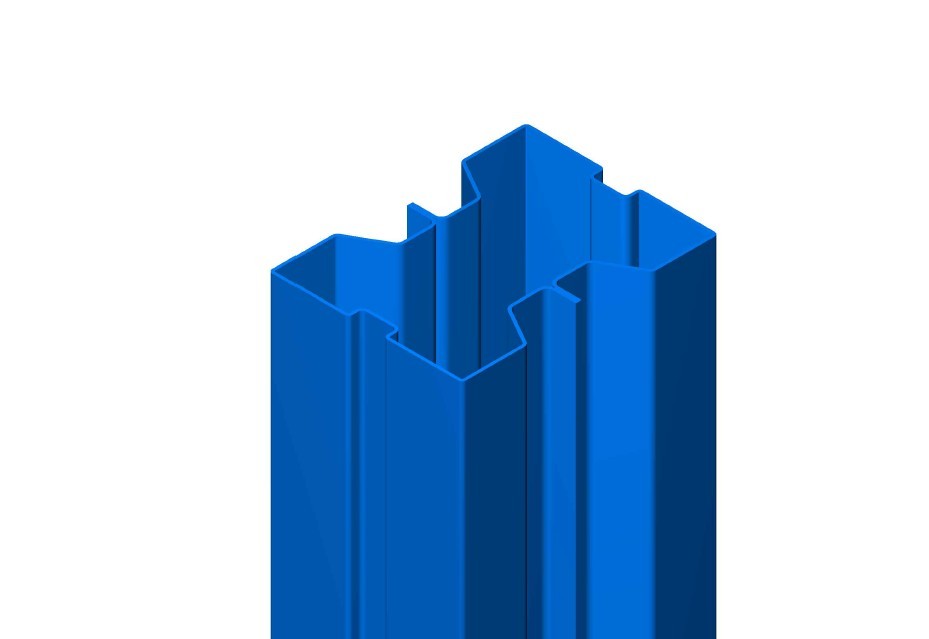

1. Column: General specification: middle A column, middle D column (old and new), heavy storage shelf column (80 * 8090) material Q235;

2. Shelf beams: commonly used 50 * 30 * 40 * 45P beams, welded beams;

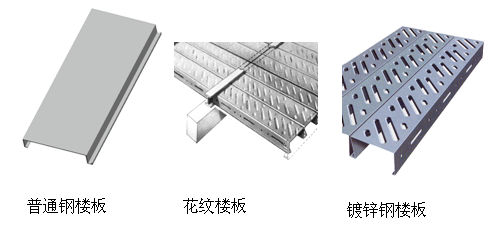

3. Shelf steel plate laminate: 0.7-1.2 cold-formed thin steel plate bending, material: Q235;

4. Ground Beam: Several kinds of P-shaped steel pipe angle steel commonly used, rolling channel steel (80 * 40 * 2.5);

5. Floor: Common specifications, smooth floor;

6. Stairs: tread pattern steel, side plate: rolling channel steel, guardrail for 35 pipes;

7. Guardrail: usually composed of 32,25 round steel tubes;

1. Customized data provided by attic shelves: total length, width, height and available net height (net height for removal of roof beams and other obstacles);

2. Data of Barriers and Net Height of Warehouse: Warehouse Height Dimensions are taken from Net Height of Ground to Actual Available Distance of Top Beam. Supporting columns, supporting beams, etc. are regarded as obstacles. Please mark the exact location, size and number of obstacles carefully.

Tips: Customized attic shelf net height needs at least 4m, minimum not less than 3.8m, reserve a certain workspace;

3. Warehouse Ground Layer: Due to different operation levels, a small number of joint warehouses or workshops may lead to uneven and undulating ground, and quickly communicate with businessmen to avoid cargo caused by inclination. The deformation of the shelf is enlarged, which will lead to collapse.

4. Storage weight of goods is data: > The weight of goods needed can be customized as: 100kg-1500kg, the weight of goods can directly depend on the material of goods, so this is not;

5. Provide the span data of supporting columns: span between supporting columns;

Customization process for loft shelves:

1: Buyer is requirement for shelf system or supplier is requirement for on-site inspection;

Usually it should include: merging plan, unit (packing cargo specifications, characteristics, weight, unit pallet cargo specifications, stacking height and carrying capacity, entry storage method, mechanical storage, automatic storage and storage equipment, storage requirements, entry and exit frequency requirements, management system requirements, control methods, etc.

2: Selection of supplier production planning design;

3: Solution discussion and optimization, procedure rationality, optimization evaluation;

4: Quote, select and sign the contract.

5: Detailed technical design of fruit system, manufacture of shelf system (preparation, processing, surface treatment, packaging, etc.);

6: Safety of shelf system - acceptance;

Reminder:

In the planning of loft shelf solutions, the following points should be noted.

1. Types of warehousing shelves;

2. Bearing the weight of each shelf and floor;

3. The number of floor designs, the width and degree of ladders;

4. Building area and site leveling, windows and other factors (water pipes, fire protection, cables, etc.);

5. Where do you need to add guardrails, doors, heights and styles?

6. Whether the floor is a walking car or a moving car;

7. What are the special requirements?

8. Foundation thickness, mud label;