Shuttle rack is an efficient, high density and low cost storage method. Compared with the shelf, the storage capacity is equivalent, but it is safe and reliable, and the shelf is not easy to damage. This rack needs to match the shuttle and be rechargeable. Driven by batteries, the shuttle truck travels on the track and enters a specially designed rack tunnel. Through lifting plates and positioning sensors, each cargo will be transported to the farthest storage location in the tunnel. It is easy to control the entry of goods by remote control forklift.

Structural characteristics of shuttle rack: It mainly consists of three parts: rack, shuttle and forklift. The shuttle can lift the pallet itself and run along the track of the rack lane, transporting goods from the entrance to the lane or from the lane to the exit.

Shuttle shelves are favored by refrigerated users. Nowadays, when the cost of land is increasing and the cost of personnel and operation is high, the storage industry with increased space and manpower needs to face enormous challenges. "Shuttle shelf high density pallet storage system" is your correct choice! The pushing frame shuttle has advanced performance and reliable technology, which can greatly improve the logistics operation efficiency of users. The shuttle tray storage system consists of a shuttle truck, a battery-powered shuttle truck and a forklift truck. The shuttle truck is on the track below the tray. It can run on the tray to store the goods on the tray or take them out of the tray.

1. Anti-foreign body collision design

2. Anti-collision design for multi-vehicle operation

3. Laser positioning and protection system, no anti-collision mark on orbit

4. Design to Reduce Malignant Work Failure

5. The battery is dead. When battery power is insufficient, stop at the entrance and wait for treatment.

1. Pallets

2. Store the same items in each lane

3. Shelf height is limited by forklift operation height

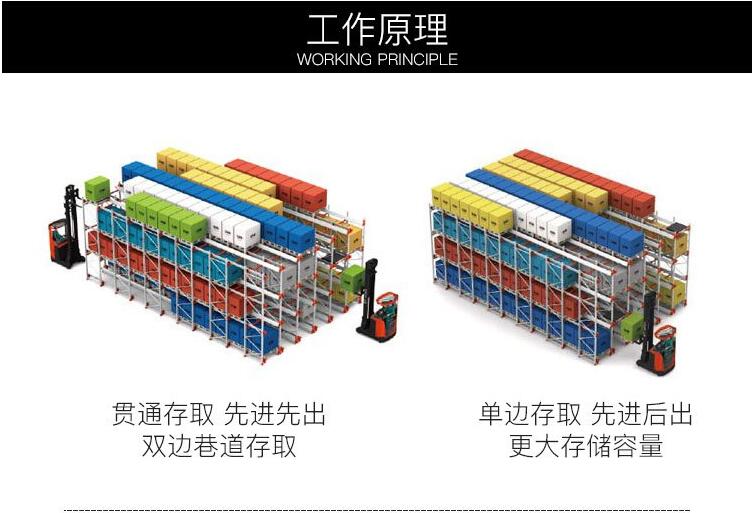

4. Two ends or one end of the goods (FIFO or FIFO)

5. Rolling racks, extruded racks, and powerful competitors for autopilot

6. Suitable for refrigeration

The performance of shuttle rack is as follows:

Achieving the highest centralized storage of pallet goods, greatly reducing the cost of warehouse construction

Goods are first-in, first-out, first-in and free to choose.

No need to enter the shelf, high loading and unloading efficiency.

Seismic safety performance is much higher than self-driving rack

1. Achieve the highest concentration of pallet cargo storage and greatly reduce the cost of warehouse construction.

2. Goods First in First Out, First in, Free to Choose

3. Remote operation, no input, high efficiency

4. Seismic safety performance is much higher than that of common shelves.

5. Compared with push shelves, push shelves and gravity shelves, the overall cost is lower.